Formwork Design & Installation

Formwork Design & Installation

Steel Rebar Installation

Top Slab - Travelling Falsework

Top Slab - Travelling Falsework

Top Slab formwork mounted on a travelling falsework fixed on rail.

Hydraulically operated travelling formwork system enabled a 30m long, double box, 8 day pour cycle. The formwork was struck, moved and re-positioned in 1 hour.

Top Slab formwork mounted on a travelling falsework fixed on rail.

Hydraulically operated travelling formwork system enabled a 30m long, double box, 8 day pour cycle. The formwork was struck, moved and re-positioned in 1 hour.

Project - 2014-2019

Project - 2014-2019

Project - 2014-2019

Steel fixing in close and strong partnership with third party company.

-

Cutting bending & fixing of 40,000 tons of rebar (10mm Ø to 40mm Ø)

-

Installation of 80,000 couplers

-

Installation of 170 km of Glass Fiber Reinforced Polymer (G.F.R.P.)

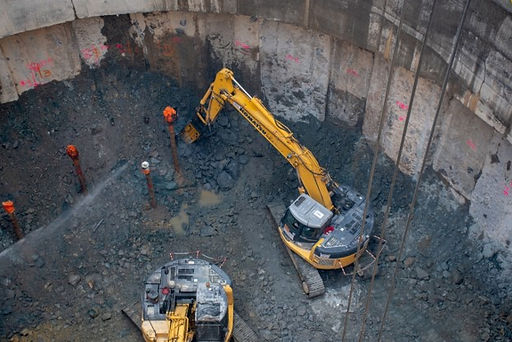

Shaft Excavation

Excavation with multiple material types such as reclamation fill, marine deposit and alluvium.

We have experience to manage large fleet of excavator, telescopic boom, dump truck, dozer.

Material Transportation and Mixing

Surcharge installation & removal, material screening, concrete block breaking & crushing to size small block

Our team has the experience to manage the material transportation in a cost-effective way.

Backfill

Backfill in restricted space with the use of telescopic equipment